Informing about the potential of additive manufacturing

Overview

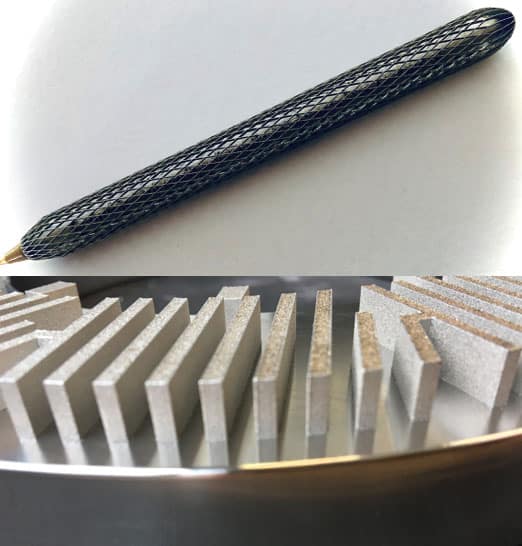

Additive manufacturing processes – 3d printing or printed electronics – offer completely new possibilities for designing products and for innovating processes and business models.

While 3d printing is particularly suitable for mass production, 3d printing processes are initially suitable for single piece and small batch production. However, one-off production and small series production is also found in every company that produces medium and large series. Namely in the form of spare parts for machines and systems or in the form of tools (handling tools, shaping tools).

The effective use of 3D printing therefore always depends on the creativity of the responsible designers and their knowledge of possible uses of 3D printing processes.

3D printing goes hand in hand with completely new design principles. Instead of leaving the design and dimensioning of components by hand to designers, they take on a control role and leave the design and dimensioning to software (parametric and generative design).

In addition to potential, additive manufacturing processes also have limitations. Raising the potential and circumventing these restrictions requires gaining of experience and the individual consideration of each task together with experts.